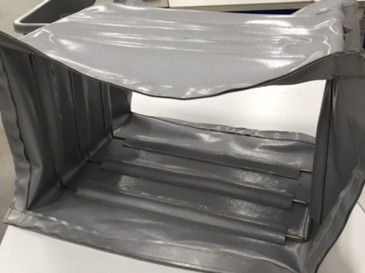

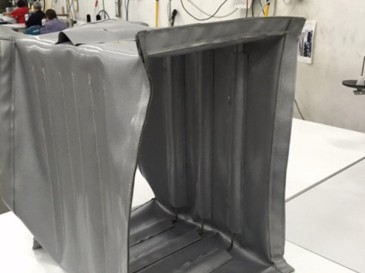

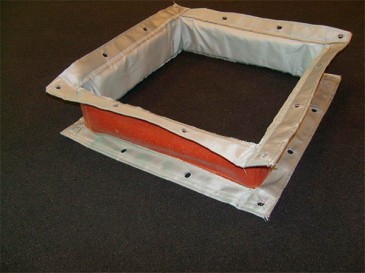

Fabric expansion joints

The employee responsible for the choice of fabric extension joints has to consider many influencing factors, such as: whether the medium is corrosive, the movement of the construction, vibrations that may occur during the production process, pressure differences, and internal and extreme temperatures.

Tailored solutions are essential to the continuity of a production process. The use of high-quality materials saves on maintenance and possible interruptions to production. The cooperation between us as manufacturer and you as client is our priority. This way, we can offer you a detailed quote with the right technical specifications.

Individual composition of fabric extension joints

Dimensions, design, and usage conditions are often unique in industrial applications. There is often no standard solution. Rather, having to tailor the fabric extension joints to the situation is the standard situation. Our engineering department would therefore like to receive some information from you. We have developed a standard questionnaire to facilitate this. That way, we can meet the specific wished and demands of the client with a “tailor-made” fabric extension joint.

Areas of application

- Ventilation ducts and fans

- Food industry

- Chemical industry – fabric extension joints

- HVAC systems - flexibles between units

- Offshore - Casings

- Power plants - Turbine and compressor

- Shipyards – exhaust channels (Fire-resistant)